Deviating speed and altitude indications, Boeing 737-800NG, OO-JAV, Amsterdam Airport Schiphol

Link to view full Dutch Safety Board Quarterly Aviation Report July – September 2021

On 3 October 2020, at approximately 08.30 hours the Boeing 737-800 was climbing out of Amsterdam Airport Schiphol (hereafter Schiphol) for a passenger flight to Madeira. While passing FL80, the first officer (pilot flying) noticed a sudden change in indicated airspeed of about 15 knots on his Primary Flight Display (PFD). When passing FL110, the captain and the first officer checked the altitude indications on their PFDs and noticed a difference of 400 feet with the standby altimeter. These differences in altitude and airspeed indications continued intermittently until after reaching the cruising altitude of FL360. Therefore, the flight crew performed the “Airspeed Unreliable” checklist to analyse and solve the unusual situation. Initially, the crew analysed the captain’s altitude indication to be reliable. Meanwhile, the flight crew decided, in coordination with the airline’s operations centre, to return to Schiphol. During the return, it became apparent that the captain’s altimeter showed erratic indications again. Hence, the “Airspeed Unreliable” checklist was run for a second time and now it was concluded that only the flight information from the Integrated Standby Flight Display (ISFD) was reliable. The flight crew continued the return flight while using the ISFD and made an uneventful landing at Schiphol. On the ground, the flight crew found out that the captain’s and the first officer’s static port on the right hand side of the aircraft was partially covered with transparent plastic and tape.

At the time of take-off, the visibility was more than 10 kilometres and de ceiling was few to broken at 1,200 feet. Along the aircrafts flown route from the southern-western part of Holland until the point of return, just past the western tip of Normandy, France, the aircraft encountered a frontal zone with multi layered clouds up to FL350. During the approach and landing at Schiphol the aircraft encountered fair weather conditions similar to the weather at the time of take-off.

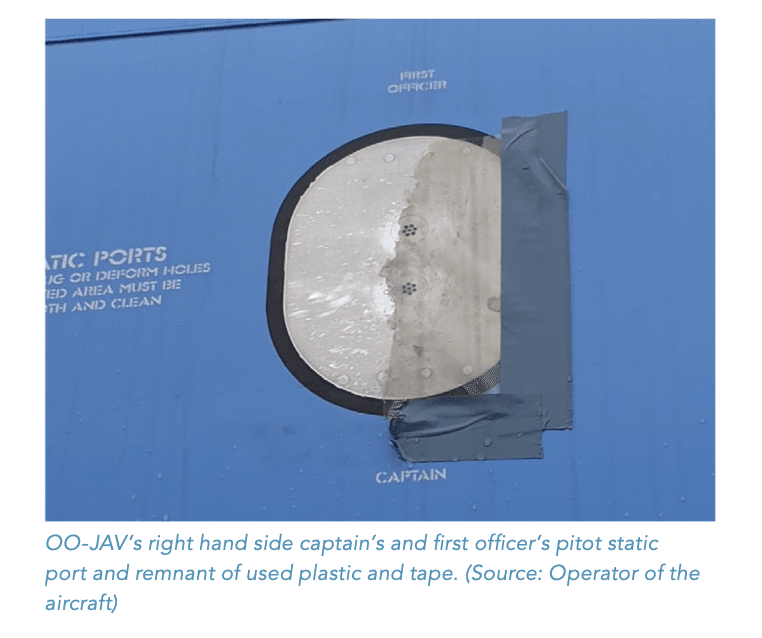

The investigation revealed that this flight was the aircraft’s first flight after returning to service from a six day parking period. For the storage of the aircraft, among others, the primary static ports were covered to prevent water, dirt or insects from entering the pitot static system. Normally, the operator provided the maintenance crews with pre-fabricated orange placards to cover the static ports. However, these placards were not available at the maintenance facility anymore. The COVID-19 pandemic flight restrictions caused a large number of aircraft to be parked in storage, which created an increased demand on these placards. Therefore, the maintenance crew searched for and used the most suitable material that was available. This led to the covers being made from clear plastic foil and adhesive tape that had the same colour as the surrounding fuselage of the static port (see figure below). The crew indicated that they were content with getting the aircraft covered and ready for parking with the available material.

The manufacturer’s aircraft maintenance manual provides specific guidance on how to fabricate plastic covers for static ports. The manual instructs to use specific orange tape with “Remove Before Flight” printed on it and specific adhesive tape. The manual also instructs to make an orange streamer and attach it to the static port cover. In addition, to get the attention of the flight crew, a ”Static Ports Covered” tag has to be attached to the left control wheel in the cockpit. The maintenance crew had indicated that they were not entirely familiar with these procedures as they were normally provided with readymade placards. Besides, they were not used to attach streamers to the placards or to attach premade cautionary tags to the left control wheel.

When the aircraft was returned to service, the next maintenance crew did not remove the cover on the primary static port on the right hand side of the aircraft. On the day of the occurrence, the maintenance crew that had prepared the aircraft for flight and the flight crew, did not notice that the static port was still covered during their pre-flight inspections either. Noted that these inspections were performed during hours of darkness.

The following four factors were contributing to this serious incident. First, the normalized maintenance practice to cover the primary static ports with readymade placards. This practice was different from the aircraft’s maintenance manual procedure. Amongst maintenance crews, the normalization led to unfamiliarity with the maintenance manual procedure and materials to be used. Second, the intention to get the aircraft into parking with the material that was at hand. Third, the low observability of the plastic and adhesive tape used, that made it difficult to notice the covers; especially in combination with low light conditions. And fourth, the expectation bias to see orange coloured covers and streamers.

Altogether, the Dutch Safety Board emphasizes that standard maintenance procedures or approved alternate procedures must be followed. In this way, the safety operation of aircraft is ensured.

The incorrect working of the pitot static system causes the presented airspeed and altitude information to become unreliable. These unreliable indications may cause difficulties for the pilots to safely control the aircraft. When these unreliable indications are combined with unfavourable environmental conditions such as cloud layers, the unsafe situation may worsen because pilots are not be able to use outside references -horizon- to aid in controlling the aircraft. During this occurrence the pilots were able to safely fly the aircraft, despite a cloud layer that was present for the majority of the flight. Nevertheless, pitot static system malfunctions have led to serious incidents and accidents in the past. It is therefore emphasized that maintenance and flight crews must verify that the pitot static system is clear of covers, placards or tape during inspections and preparation for flight to ensure the safety of flight.

The Dutch Safety Board has issued an interim warning with the aim to raise airlines’ and maintenance organisations’ awareness to the safety risks that can increase when aircraft are retuned to service following a period of storage.

The operator and maintenance organizations both performed an investigation into the occurrence and shared their findings with the Dutch Safety Board. The Dutch Safety Board used the information from these reports and conducted interviews for this investigation.