Maxwell, NASA’s e-plane, is running out of runway

An experimental, potentially revolutionary all-electric airplane designed by NASA will soon be taking its first test flight, which will mark a major milestone for battery-powered aviation. However, the program already appears destined to fall short of its lofty goal to exploit the unique features of electric propulsion to rewrite the design rules for modern aircraft. Its time and funding has nearly run out.

Part of the agency’s storied X-plane program, the X-57 Maxwell set out with the ambitious goal of tackling two grand challenges in aerospace engineering simultaneously. Not only did it aim to show that an airplane could be powered entirely by electricity, it also planned to demonstrate the significant gains in efficiency and performance that could be made by switching from two large engines to many smaller ones evenly distributed across the wings—a configuration known as a “blown wing.”

The plan was to demonstrate both of these propositions through a series of increasingly advanced test vehicles. Ultimately though, the complexity of the first challenge, compounded by disruptions caused by the COVID-19 pandemic, saw timelines repeatedly pushed back. As a result, the project’s leaders say it no longer has the funding to progress to the latter stages of the program.

“It turned out to be actually a pretty tall order to work through all of those airworthiness, and qualification, and design challenges.”

—Sean Clarke, NASA

The first iteration of the X-57, a modified Tecnam P2006T light aircraft whose gas-powered engines have been replaced with electric motors, will take flight this coming spring or possibly summer. (As of early January, NASA is still unclear as to precisely when that maiden voyage will be. NASA officials Spectrum contacted could only narrow the timeframe down to “first half of 2023.”) That will be a significant achievement, making the X-57 one of just a handful of electrically powered aircraft to get off the ground. But the team say they plan to wrap up flight testing by the end of the year and will no longer be building more advanced designs featuring novel wing configurations and distributed propulsion, such as the blown wing.

“We tried to do a very ambitious thing. Trying to do a new type of airframe and a new motor project is not very typical, because those are both very, very challenging endeavors,” says Nick Borer, deputy principal investigator for the X-57 project at the NASA Langley Research Center. “The agency funds a lot of different things and they’ve been very generous with what they’ve provided to us. But there are priorities at the top and eventually, you’ve got to finish up.”

The project’s ultimate goal was to take advantage of the benefits of electric propulsion to reimagine the design of aircraft wings. For instance, in the case of that blown wing: the large number of motors and props on the leading-edge force air at high rates over the wing, which can generate significant lift even at low speeds. This makes it possible to take off from shorter runways and can also allow you to shrink the size of the wing, reducing drag and boosting cruise efficiency.

The design is difficult to achieve with conventional combustion engines, because they are relatively heavy and become increasingly inefficient as they are scaled down in size. The same is not true of electric motors though, which means it’s relatively simple to switch from several large motors to many smaller ones distributed along the wing.

The current iteration of the X-57, pictured here, is powered by two electric motors and is based at the NASA Armstrong Flight Research Center in California.CARLA THOMAS/NASA

The current iteration of the X-57, pictured here, is powered by two electric motors and is based at the NASA Armstrong Flight Research Center in California.CARLA THOMAS/NASA

The final design iteration of the X-57 had six small electrically powered propellers across the front of each wing. The wings themselves would be only 40 percent of the size of a conventional P2006T wing. The design also featured two larger motors mounted on the tips of each wing, which would further reduce drag by counteracting the vortices normally produced at the end of each wing. Because the high lift generated by the smaller propellers along the leading edge would only be needed at take-off, these were designed to fold up once at cruising altitude to further reduce drag.

“The whole idea of an X-plane is to do something that has never been done before, and so I think it is just normal to expect that there is a learning curve.”

—Sergio Cecutta, SMG Consulting

Altogether these aerodynamic innovations would slash the planes’ power consumption at cruise by as much as a third, according to Borer. Electric motors are also about three times more efficient in terms of their power-to-weight ratio compared to gasoline-burning ones, he adds, so combined these design changes were expected to lead to a roughly fivefold reduction in energy requirements while flying at cruise speeds of around 280 kilometers per hour.

Switching to electric propulsion turned out to be more complicated than envisioned. The team had to completely redesign their battery packs in 2017 to avoid the risk of catastrophic fires. The high voltages and power levels required for electric aviation also posed significant complications, says Borer, requiring several iterations of the systems designed to protect components from electromagnetic interference.

Early on in the project they also found that state-of-the-art transistors able to withstand high power levels couldn’t tolerate the vibrations and temperatures involved in flight. This was resolved only recently by switching to a newer generation of silicon carbide MOSFET modules, says Sean Clarke, principal investigator for the X-57 project at the NASA Armstrong Flight Research Center in California. “It turned out to be actually a pretty tall order to work through all of those airworthiness, and qualification, and design challenges,” he says.

This led to delays that will mean the more ambitious goals of the project may not come to fruition, but Borer hopes that others will be able to pick up from where they left off. The team has been regularly publishing their findings and data as they’ve progressed, he says. They are also actively contributing to standards for electric aviation and are working with regulators to help develop aircraft certification processes. “We’re pushing out everything that we can,” says Borer.

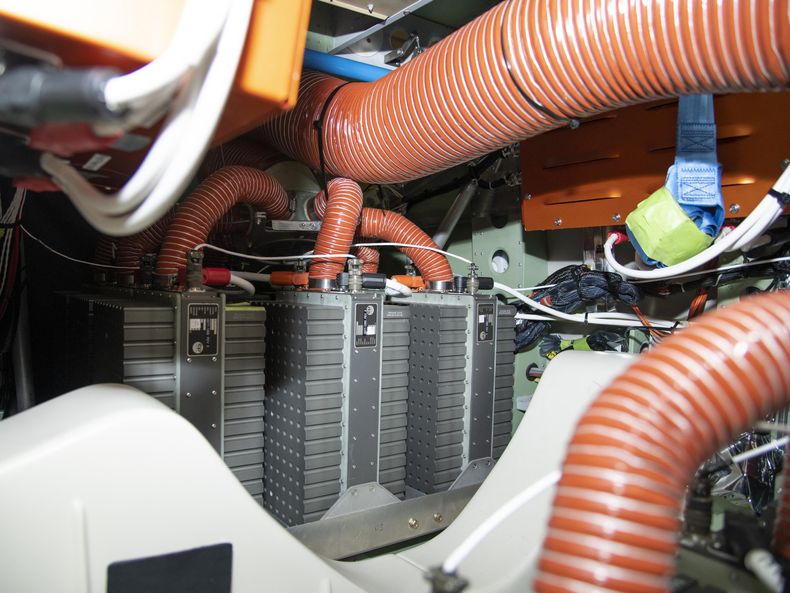

The X-57’s custom-made battery packs installed in the aircraft’s cabin provide all the aircraft’s power, rather than the JET A/A-1 fuel that powers most aviation today. LAUREN HUGHES/NASA

The X-57’s custom-made battery packs installed in the aircraft’s cabin provide all the aircraft’s power, rather than the JET A/A-1 fuel that powers most aviation today. LAUREN HUGHES/NASA

This information sharing has already borne fruit. NASA’s main subcontractor for the project California-based Empirical Systems Aerospace has been able to commercialize the X-57’s battery pack design, and the agency has a technology-transfer agreement with Virginia-based electric-aircraft designer Electra, which involved the team sharing information on their aerodynamic innovations. The company that NASA initially contracted to build their electric motors, Joby Aviation, has also gone on to develop their own electric vertical take-off and landing (eVTOL) vehicle and is today one of the leaders in the industry.

This is the beauty of a publicly funded effort like the X-57, says Sergio Cecutta, founder and partner at SMG Consulting, who covers the electric-aviation industry. Unlike a private development effort, he says, all of the advances and lessons that have come out of the project will be in the public domain and can spread throughout the industry. And while it may not have achieved its most ambitious goals, Cecutta says it has done exactly what was intended, which was to remove some of the roadblocks holding back electric aviation.

“The whole idea of an X-plane is to do something that has never been done before, and so I think it is just normal to expect that there is a learning curve,” he says. “In the end, you want to lay the groundwork for the industry to become successful, and I think on that metric, the X-57 has been a successful project.”